-

AGRICULTURAL MACHINERY

- BRANDS

- Tractors CASE IH

- Grain-harvesting combines

-

Sowing machinery

- KUHN Planter 3 Select precision seed drill

- Sowing complex KUHN ESPRO _ RC

- Precision seeder KUHN KOSMA

- Case IH SDX 30/40 pneumatic sowing machine

- BEDNAR OMEGA OO_FL sowing machine

- A wide seed drill BEDNAR EFECTA CE

- Grain seeder BEDNAR CORSA CN

- Pneumatic precision seed drill KUHN MAXIMA 3 TRM E

- MATADOR MO sowing machine

- Sprayers

- Tillage machinery

-

Harvesting machinery

- Olimac Drago 2 corn harvester

- Olimac Drago GT corn harvester

- Olimac Gold sunflower harvester

- Franco Fabril SF sunflower harvester

- Case IH 3020 TeraFlex

- Case IH Grain harvesters

- Case IH 3050 Varicut

- MacDon FD2 corn harvesters

- Grain reaper Case IH 2030

- Case IH 4408 corn harvester

- Case IH 4412 corn harvester

- PW8 Pick-up Header

- Corn harvester FRANCO FABRIL MH870

- Mower

- Balers

- Rollers

- Telescopic loader

- USED Machinery

- SAFEGUARD WARRANTY

-

PRECISION AGRICULTURE

- AgroDrones & UAV

-

Tractor solutions

- Raven CR7 Field Computer

- XCN - 2050 display

- Дисплей XCN-1050

- XCN-750 display

- Autopilot Electric Motor Drive automatic driving system

- Automatic driving system EZ-Pilot Pro

- AFS AccuGuide precision farming system

- Automatic water system Sveaverken F100

- Raven hydraulic autopilot for unprepared equipment

- Trimble Autopilot automatic control system

- Sprayer solutions

- Combine solutions

- Trailed implements solutions

- Correction service

- Maintenance of data

- USED MACHINERY

- SERVICE

- PARTS

- WORK AT TITAN

- SPECIAL OFFERS

A new generation of FENIX FO_PROFI universal cultivator model series

10/27/2022

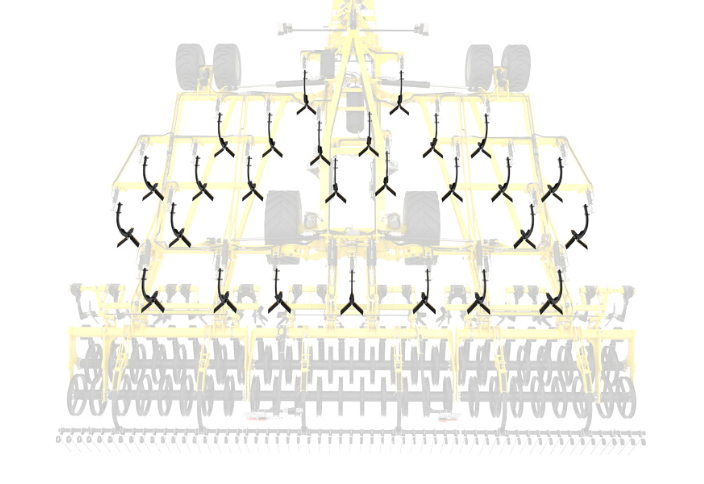

Universal (share – chisel) cultivators play an irreplaceable role in farming. The popularity of such machines continues to grow. For 2023, BEDNAR is introducing a new generation of the FENIX FO_PROFI universal cultivators to the market. The series includes four models with a working span from 4 to 7.9 m suitable for intense soil cultivation in one pass with the maximum working depth of 35 centimetres.

“We decided to develop the new generation of the FENIX FO_PROFI cultivators based on our experience of many years and findings from various markets. After two years of intense testing in various conditions, we are introducing a new product that excels in many technical and structural components. The FENIX FO_PROFI is a multi-purpose machine that can do most of the operations in your fields and in almost any weather,” adds Jan Bednář, the Sales Director.

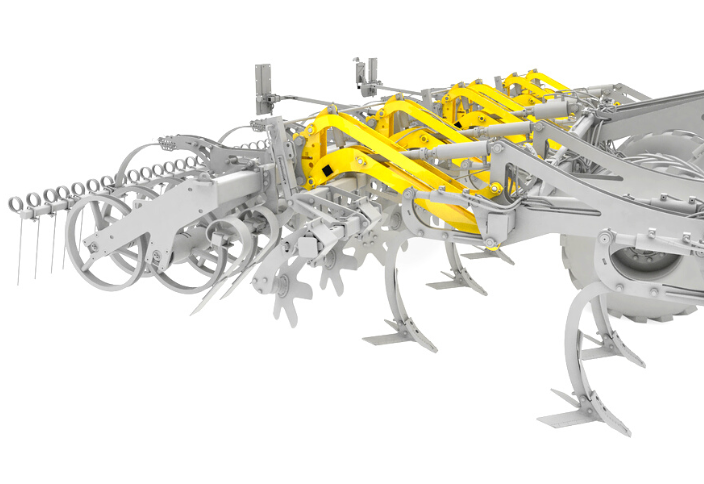

Four-row Tine Configuration for Improved Loosening Effect

The new generation of FENIX FO_PROFI has a four-row configuration of the main working parts - the tines. The individual tines are sufficiently spaced, both inside the row and between the individual rows. The new structural design offers outstanding throughput when processing large quantities of organic matter thanks to the high clearance of 80 cm of the main frame.

The arrangement of the individual tines into a V-shape contributes to minimal draft resistance of the machine. The suitable arrangement and shape of the working parts provides intense soil cultivation, including even mixing of organic matter up to the depth of 35 centimetres. The tines can be fitted with chisels with a width of 80 and 60 mm, or LONG-LIFE chisels with a width of 80 and 40 mm, fitted with carbide plates for higher durability. The cultivating chisels can also be fitted with wings, 125 and 185 mm; the 185 mm version also comes in the LONG-LIFE configuration. The basic equipment of the machine includes hydraulic working depth regulation; or customers can also choose electric-hydraulic regulation. The machine is comfortably controlled from the tractor cabin.

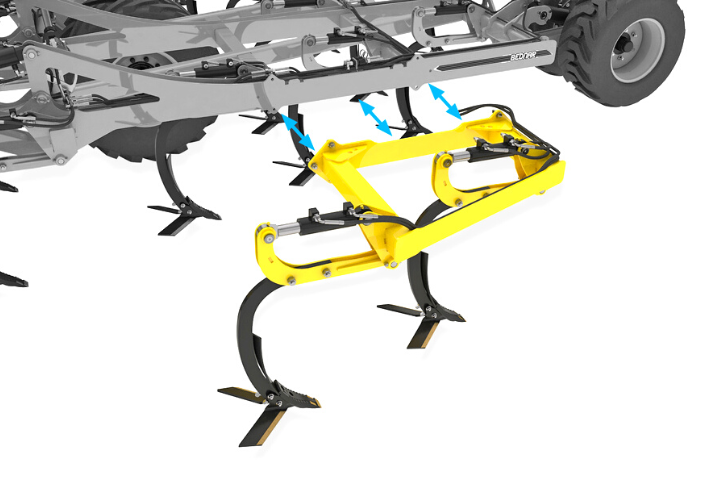

New Working Parts Protection

The working parts of the FENIX FO_PROFI universal cultivator can be fitted with three different types of overload protection. The basic one is the shear bolt protection, suitable for very light soils. The horizontal spring protection with a release force of 480 kg is the most frequently used protection in these machines. It is suitable for most regular soil conditions.

The novel hydraulic protection offers a release force of up to 550 kg. The robust construction makes this type of protection ideal for medium-heavy and heavy soils.

Integrated Transport Axle – Proven Design by BEDNAR

The new generation of the FENIX FO_PROFI machines includes the proven design of the integrated transport axle. The fourth, single row of tines is mounted behind the transport axle for a better quality of work. When it is wet, the packers can be easily deactivated, and soil is cultivated without compaction. Moreover, the integrated axle reduces the radius diameter at headlands and improves manoeuvrability of the machine during transport.

Adjusting the Working Width to the Current Conditions

The adjustment of the working width to the soil conditions or tractor properties is an interesting advantage of the FENIX FO 6004 PROFI model. The FENIX FO 6004 PROFI model offers the option to adjust the working width from 6.7 to 7.9 metres by easy installation of the set for additional side sections. The working width can then be easily adjusted to the current requirements, also for the FENIX FO 8004 PROFI model.

A Wide Range of Optional Equipment, Not Only for the Main Parts

Thanks to the well-thought-out design of FENIX FO_PROFI, you can perform deep soil cultivation, including quality levelling and soil recompaction in one pass. The four rows of tines are followed with a levelling section that can be equipped with the levelling backfillers or levelling discs, controlled mechanically or hydraulically conveniently from the tractor cabin.

Moreover, the Crushbar leveller can be installed in front of the rear packer for the final soil levelling. There is a wide range of packers available, both single-row (tubular packer, V-RING) and double-row (double V-RING, double U-RING). Moreover, an extra leveller can be mounted behind the rear packer.

The parallelogram for rear packers is an important technical design. The packers are equipped with a parallelogram that provides perfect terrain tracing and maintains the set working depth.

Titan Machinery Ukraine specialists will help you choose units for sowing, processing, and harvesting professionally and according to your needs. An extensive network of warehouses of original spare parts and service workshops are working for you throughout the territory of Ukraine to keep your machinery always in good condition and ready for work. We are always there and help our customers in any circumstances. Please call 0 800 50 8080.

INDUSTRIES

BRANDS