-

AGRICULTURAL MACHINERY

- BRANDS

- Tractors CASE IH

- Grain-harvesting combines

-

Sowing machinery

- KUHN Planter 3 Select precision seed drill

- Sowing complex KUHN ESPRO _ RC

- Precision seeder KUHN KOSMA

- Case IH SDX 30/40 pneumatic sowing machine

- BEDNAR OMEGA OO_FL sowing machine

- A wide seed drill BEDNAR EFECTA CE

- Grain seeder BEDNAR CORSA CN

- Pneumatic precision seed drill KUHN MAXIMA 3 TRM E

- MATADOR MO sowing machine

- Sprayers

- Tillage machinery

-

Harvesting machinery

- Olimac Drago 2 corn harvester

- Olimac Drago GT corn harvester

- Olimac Gold sunflower harvester

- Franco Fabril SF sunflower harvester

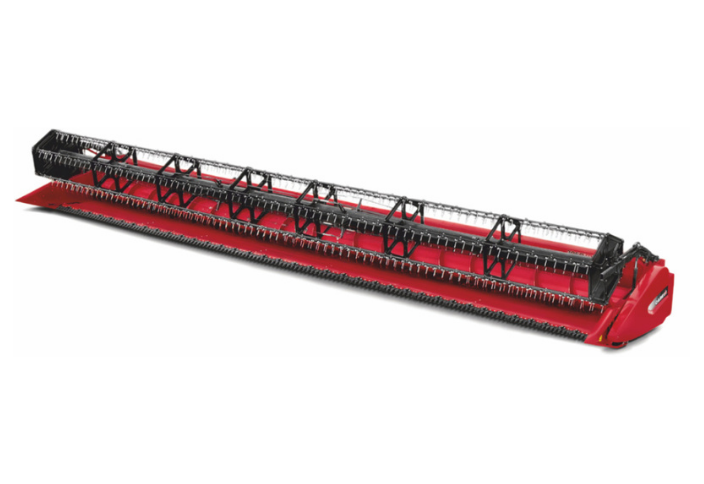

- Case IH 3020 TeraFlex

- Case IH Grain harvesters

- Case IH 3050 Varicut

- MacDon FD2 corn harvesters

- Grain reaper Case IH 2030

- Case IH 4408 corn harvester

- Case IH 4412 corn harvester

- PW8 Pick-up Header

- Corn harvester FRANCO FABRIL MH870

- Mower

- Balers

- Rollers

- Telescopic loader

- USED Machinery

- SAFEGUARD WARRANTY

-

PRECISION AGRICULTURE

- AgroDrones & UAV

-

Tractor solutions

- Raven CR7 Field Computer

- XCN - 2050 display

- Дисплей XCN-1050

- XCN-750 display

- Autopilot Electric Motor Drive automatic driving system

- Automatic driving system EZ-Pilot Pro

- AFS AccuGuide precision farming system

- Automatic water system Sveaverken F100

- Raven hydraulic autopilot for unprepared equipment

- Trimble Autopilot automatic control system

- Sprayer solutions

- Combine solutions

- Trailed implements solutions

- Correction service

- Maintenance of data

- USED MACHINERY

- SERVICE

- PARTS

- WORK AT TITAN

- SPECIAL OFFERS

Case IH Axial Flow 7250™

Designed to meet the challenges of high-yielding crops, climate change and the constant pursuit of efficiency, Case IH's Axial-Flow® combines are redefining the field of grain harvesting technology. Thanks to a number of state-of-the-art features, including AFS Harvest Command™ automated harvesting technology, the 250 series combines meet the demands of large modern farms and contractors: high-speed harvesting, increased threshing capacity even in the most difficult conditions and unsurpassed grain quality. Inclined chamber, rotor, grain hopper, unloading system and automatic adjustment of settings are designed to ensure high throughput and simplify grain harvesting operations.

Engine

Model: FTP Cursor 11 / Tier II

Capacity: 11.1 l

Rated power: 431 hp. (317 kW)

Maximum power: 498 hp. (366 kW)

Fuel system type: High Pressure Common Rail

Fuel tank capacity: 1125 l

Running gear

Wheel configuration: Front wheel drive (2WD)

Transmission type: 2-speed hydrostatic drive

Standard size of the wheels:

Front: Single, 900/60R32 or rubber caterpillars 76 cm wide

Rear: Single, 600/70R28

Threshing and separation systems

Threshing and separation systems type: Single-rotor/sieve mills

Rotor: Drive from Power PlusTM continuously variable transmission with 3 ranges

Diameter on the outer edge of the whips is 762 mm, diameter of the rotor tube is 649 mm

Rotor length is 2,623 mm

Rotor rotational speed is 220 to 1,180 rpm

Rotor cage: 2 threshing modules and 4 separation modules

Capture angle of threshing modules is 180°, and that of separation ones is 180°

Contaminants removal: Contaminants removal area is 8.59 m2

“Cross Flow” fan, 40 blades, 392.5 mm diameter

Finishing milling device available

Type of non-grain portion processing system: Knife rotor installed transversely and counter-knives

Type of non-grain portion throwing system: Two vertical blade throwing devices with side deflectors

Grain loading and unloading systems

Capacity of the cleaned grains hopper: 14.4 m3

Unloading auger length: 6.7 m

Unloading auger capacity: 0.113 m3/s

Monitoring and navigation system

Monitoring: Colour touch screen of AFS Pro 700 (yield and humidity sensors optionally)

GPS navigation systems: Optional installation of autopilot, GPS navigation and mapping system is possible

Overall dimensions and weight

Length/width/height: 8.9/4.0/4.7 m

Weight (approximate): 17,735 kg

Engine

Model: FTP Cursor 11 / Tier II

Capacity: 11.1 l

Rated power: 431 hp. (317 kW)

Maximum power: 498 hp. (366 kW)

Fuel system type: High Pressure Common Rail

Fuel tank capacity: 1125 l

Running gear

Wheel configuration: Front wheel drive (2WD)

Transmission type: 2-speed hydrostatic drive

Standard size of the wheels:

Front: Single, 900/60R32 or rubber caterpillars 76 cm wide

Rear: Single, 600/70R28

Threshing and separation systems

Threshing and separation systems type: Single-rotor/sieve mills

Rotor: Drive from Power PlusTM continuously variable transmission with 3 ranges

Diameter on the outer edge of the whips is 762 mm, diameter of the rotor tube is 649 mm

Rotor length is 2,623 mm

Rotor rotational speed is 220 to 1,180 rpm

Rotor cage: 2 threshing modules and 4 separation modules

Capture angle of threshing modules is 180°, and that of separation ones is 180°

Contaminants removal: Contaminants removal area is 8.59 m2

“Cross Flow” fan, 40 blades, 392.5 mm diameter

Finishing milling device available

Type of non-grain portion processing system: Knife rotor installed transversely and counter-knives

Type of non-grain portion throwing system: Two vertical blade throwing devices with side deflectors

Grain loading and unloading systems

Capacity of the cleaned grains hopper: 14.4 m3

Unloading auger length: 6.7 m

Unloading auger capacity: 0.113 m3/s

Monitoring and navigation system

Monitoring: Colour touch screen of AFS Pro 700 (yield and humidity sensors optionally)

GPS navigation systems: Optional installation of autopilot, GPS navigation and mapping system is possible

Overall dimensions and weight

Length/width/height: 8.9/4.0/4.7 m

Weight (approximate): 17,735 kg

AGGREGATED WITH THE FOLLOWING EQUIPMENT:

TITAN MACHINERY UKRAINE qualified specialists are trained by our European partners on the regular basis. We are ready to provide you with professional support together with choosing the best solutions for your working conditions.

We are ready to provide all the information about the machinery presented on our website.

Please contact us by the number or e-mail: 0800-50-8080 / sales@titanmachinery.ua

Please contact us by the number or e-mail: 0800-50-8080 / sales@titanmachinery.ua

INDUSTRIES

BRANDS