Case IH Axial Flow 8250™

Axial-Flow 250 series combines are equipped with Case IH's most advanced automated harvesting technology - AFS Harvest CommandTM, which eliminates the need for the operator to constantly adjust the combine parameters to changing harvesting conditions during long working days.

Combines with high performance grain hoppers and unloading systems are equipped with this optional technology: it is a revolutionary autonomous system that monitors all key elements of the combine and optimizes its operating settings according to four strategies to ensure maximum performance in all harvesting conditions.

Settings such as rotor speed, rotor shroud guide position adjustment, cleaning system fan speed, and the degree of opening of the cleaning sieves are automatically and continuously adjusted in real time to guarantee the highest productivity and grain quality – without any operator intervention.

All operators will benefit from this system, but it will be especially useful for less experienced operators, as the combine will now be able to make important decisions independently and optimize performance accordingly.

10 GOOD REASONS TO CHOOSE AXIAL-FLOW®

Combines with high performance grain hoppers and unloading systems are equipped with this optional technology: it is a revolutionary autonomous system that monitors all key elements of the combine and optimizes its operating settings according to four strategies to ensure maximum performance in all harvesting conditions.

Settings such as rotor speed, rotor shroud guide position adjustment, cleaning system fan speed, and the degree of opening of the cleaning sieves are automatically and continuously adjusted in real time to guarantee the highest productivity and grain quality – without any operator intervention.

All operators will benefit from this system, but it will be especially useful for less experienced operators, as the combine will now be able to make important decisions independently and optimize performance accordingly.

10 GOOD REASONS TO CHOOSE AXIAL-FLOW®

ENGINE

Model: FTP Cursor 13 / Tier II

Capacity: 12.9 l

Rated power: 496 hp. (362 kW)

Maximum power: 571 hp. (420 kW)

Fuel system type: High Pressure Common Rail

Fuel tank capacity: 1,125 l

Capacity: 12.9 l

Rated power: 496 hp. (362 kW)

Maximum power: 571 hp. (420 kW)

Fuel system type: High Pressure Common Rail

Fuel tank capacity: 1,125 l

TRANSMISSION

Wheel configuration: Front wheel drive (2WD)

Transmission type: 2-speed hydrostatic drive

Standard size of the wheels:

Front: Single, 900/60R32 or rubber caterpillars 76 cm wide

Rear: Single, 600/70R28

Transmission type: 2-speed hydrostatic drive

Standard size of the wheels:

Front: Single, 900/60R32 or rubber caterpillars 76 cm wide

Rear: Single, 600/70R28

Threshing and separation systems

Threshing and separation systems type: Single-rotor/sieve mills

Rotor: Drive from Power PlusTM continuously variable transmission with 3 ranges

Diameter on the outer edge of the whips is 762 mm, diameter of the rotor tube is 649 mm

Rotor length is 2,623 mm

Rotor rotational speed is 220 to 1,180 rpm

Rotor cage: 4 threshing modules and 4 separation modules

Capture angle of threshing modules is 180°, and that of separation ones is 180°

Contaminants removal: Contaminants removal area is 8.59 m2

“Cross Flow” fan, 40 blades, 392.5 mm diameter

Finishing milling device available

Type of non-grain portion processing system: Knife rotor installed transversely and counter-knives

Type of non-grain portion throwing system: Two vertical blade throwing devices with side deflectors

Rotor: Drive from Power PlusTM continuously variable transmission with 3 ranges

Diameter on the outer edge of the whips is 762 mm, diameter of the rotor tube is 649 mm

Rotor length is 2,623 mm

Rotor rotational speed is 220 to 1,180 rpm

Rotor cage: 4 threshing modules and 4 separation modules

Capture angle of threshing modules is 180°, and that of separation ones is 180°

Contaminants removal: Contaminants removal area is 8.59 m2

“Cross Flow” fan, 40 blades, 392.5 mm diameter

Finishing milling device available

Type of non-grain portion processing system: Knife rotor installed transversely and counter-knives

Type of non-grain portion throwing system: Two vertical blade throwing devices with side deflectors

Threshing and separation systems. Monitoring and navigation, dimensions and weight

Capacity of the cleaned grains hopper: 14.4 m3

Unloading auger length: 6.7 m

Unloading auger capacity: 0.113 m3/s

Monitoring: Colour touch screen of AFS Pro 700 (yield and humidity sensors optionally)

GPS navigation systems: Optional installation of autopilot, GPS navigation and mapping system is possible

Length/width/height: 8.9/4.4/4.7 m

Weight (approximate): 17,735 kg

Unloading auger length: 6.7 m

Unloading auger capacity: 0.113 m3/s

Monitoring: Colour touch screen of AFS Pro 700 (yield and humidity sensors optionally)

GPS navigation systems: Optional installation of autopilot, GPS navigation and mapping system is possible

Length/width/height: 8.9/4.4/4.7 m

Weight (approximate): 17,735 kg

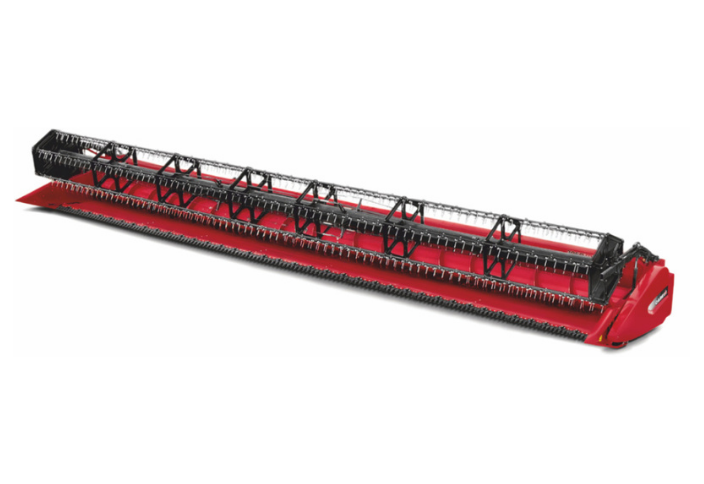

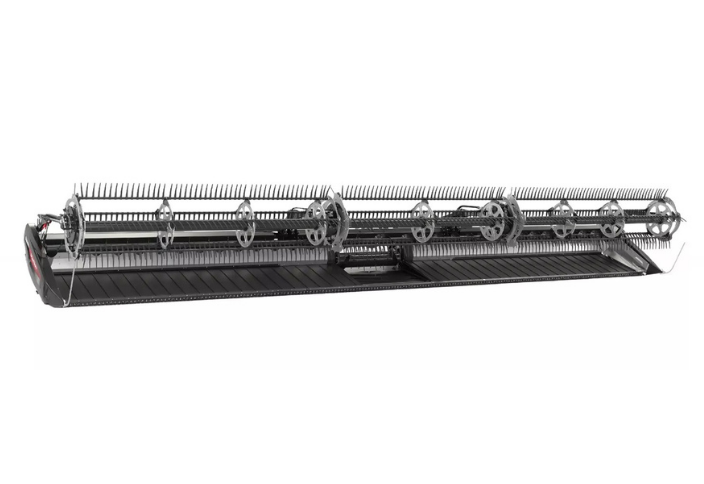

Aggregated with the following equipment:

TITAN MACHINERY UKRAINE qualified specialists are trained by our European partners on the regular basis. We are ready to provide you with professional support together with choosing the best solutions for your working conditions.

We are ready to provide all the information about the machinery presented on our website.

Please contact us by the number or e-mail: 0800-50-8080 / sales@titanmachinery.ua

Please contact us by the number or e-mail: 0800-50-8080 / sales@titanmachinery.ua